PLA is one of the most widely used materials in 3D printing, valued for its ease of use and clean results. As the material has evolved, PLA+ 3D printing filament has emerged as an upgraded alternative, offering improved performance while retaining the simplicity that makes PLA so popular.

If you’re deciding between PLA 3D printing filament and PLA+, this guide breaks down the real differences in strength, print speed, surface finish, and use cases, helping you choose the right option for your next project.

What Is PLA 3D Printing Filament?

PLA (Polylactic Acid) is a plant-based thermoplastic derived from renewable resources such as corn starch. It is known for being easy to print, environmentally friendlier than many plastics, and capable of producing high-quality surface finishes.

PLA is widely used across:

-

Hobbyist projects

-

Education and schools

-

Decorative and display models

-

Prototyping

Its low warping and minimal odour make it ideal for open-frame printers and beginners.

What Is PLA+ 3D Printing Filament?

PLA+ is an enhanced version of standard PLA. While formulations vary slightly between manufacturers, PLA+ is typically blended with impact modifiers and strength-enhancing additives to improve durability and performance.

PLA+ 3D printing filament is designed to:

-

Increase tensile strength

-

Improve layer adhesion

-

Reduce brittleness

-

Support higher print speeds

This makes PLA+ a popular choice for users who want better mechanical performance without moving to more complex materials.

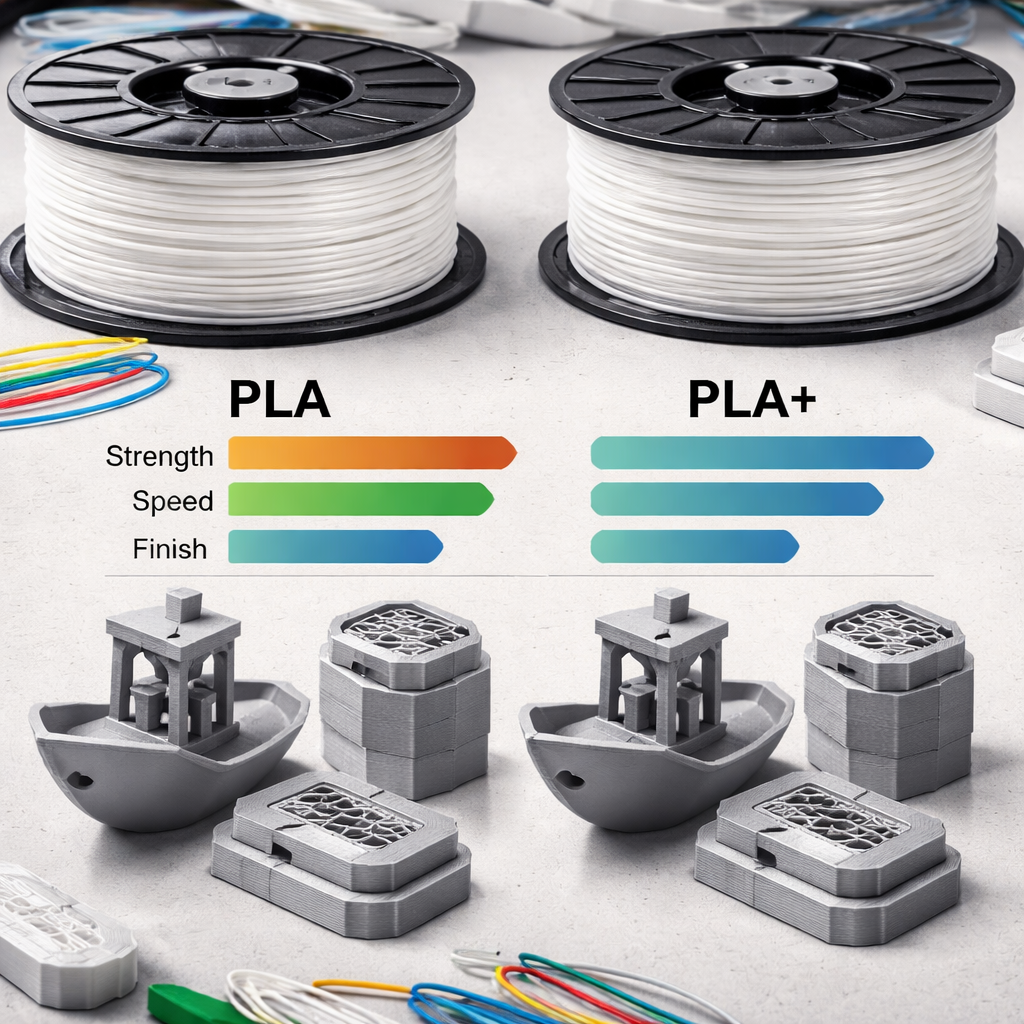

PLA vs PLA+: Strength Comparison

Standard PLA Strength

PLA provides good rigidity and surface quality but can be brittle under stress. Parts printed with PLA may crack or snap when subjected to impact or repeated mechanical load.

Best suited for:

-

Static parts

-

Display models

-

Light-duty prototypes

PLA+ Strength Advantages

PLA+ offers noticeably improved toughness and flexibility. Enhanced layer bonding allows prints to handle more stress before failure.

Best suited for:

-

Functional prototypes

-

Everyday tools

-

Brackets and mounts

-

Parts requiring improved durability

If strength is a priority, PLA+ is the better option.

PLA vs PLA+: Print Speed and Performance

Print Speed with PLA

PLA prints reliably at moderate speeds and is forgiving when settings are not perfectly tuned. This makes it ideal for consistent results, especially on entry-level printers.

Typical advantages:

-

Stable extrusion

-

Minimal tuning required

-

Excellent reliability

Print Speed with PLA+

PLA+ is formulated to support higher print speeds while maintaining strong layer adhesion. Many users choose PLA+ for faster production without sacrificing print quality.

Key benefits:

-

Improved flow characteristics

-

Better layer bonding at higher speeds

-

Reduced risk of layer separation

For users running high-speed or production-oriented setups, PLA+ offers a clear advantage.

PLA vs PLA+: Surface Finish and Appearance

Finish Quality of PLA

PLA is known for producing clean, smooth surfaces with crisp details. It is available in a wide range of colours and specialty finishes, including matte, silk, and transparent options.

Ideal for:

-

Visual models

-

Decorative prints

-

Display pieces

Finish Quality of PLA+

PLA+ also delivers high-quality finishes, though some blends may appear slightly less glossy than standard PLA. The difference is minimal and often outweighed by the improved strength.

Both materials are excellent for aesthetic prints, with PLA offering slightly more visual consistency in certain applications.

Ease of Printing and Compatibility

Both PLA and PLA+ share similar printing requirements:

-

No heated enclosure required

-

Compatible with most FDM 3D printers

-

Low warping compared to ABS or Nylon

PLA+ may require slightly higher nozzle temperatures depending on the formulation, but overall ease of use remains very similar.

For most users, switching from PLA to PLA+ requires little to no adjustment.

When Should You Choose PLA?

Choose PLA 3D printing filament if you:

-

Are new to 3D printing

-

Need excellent surface finish

-

Are printing decorative or display models

-

Want reliable, easy-to-print material

-

Prioritise visual quality over mechanical strength

PLA remains an excellent everyday filament for a wide range of projects.

When Should You Choose PLA+?

Choose PLA+ 3D printing filament if you:

-

Need stronger and tougher prints

-

Want better layer adhesion

-

Are printing functional or load-bearing parts

-

Run faster print speeds

-

Want improved durability without added complexity

PLA+ is ideal for users who want more performance while keeping PLA-level simplicity.

PLA and PLA+ Filament at 3D META

At 3D META, both PLA and PLA+ filaments are manufactured to meet strict quality standards, ensuring consistent diameter, reliable extrusion, and dependable results. With a wide range of colours and specialty variants, users can select the right material for both aesthetic and functional applications.

Whether you’re printing detailed models or durable functional parts, choosing the right PLA-based filament ensures better outcomes and fewer print failures.

Final Thoughts: PLA vs PLA+

The choice between PLA and PLA+ comes down to how you plan to use your prints. PLA excels in ease of use and visual quality, while PLA+ offers improved strength, speed capability, and durability.

For beginners and visual projects, PLA remains a strong choice. For functional prints and higher performance needs, PLA+ provides clear advantages without complicating the printing process.