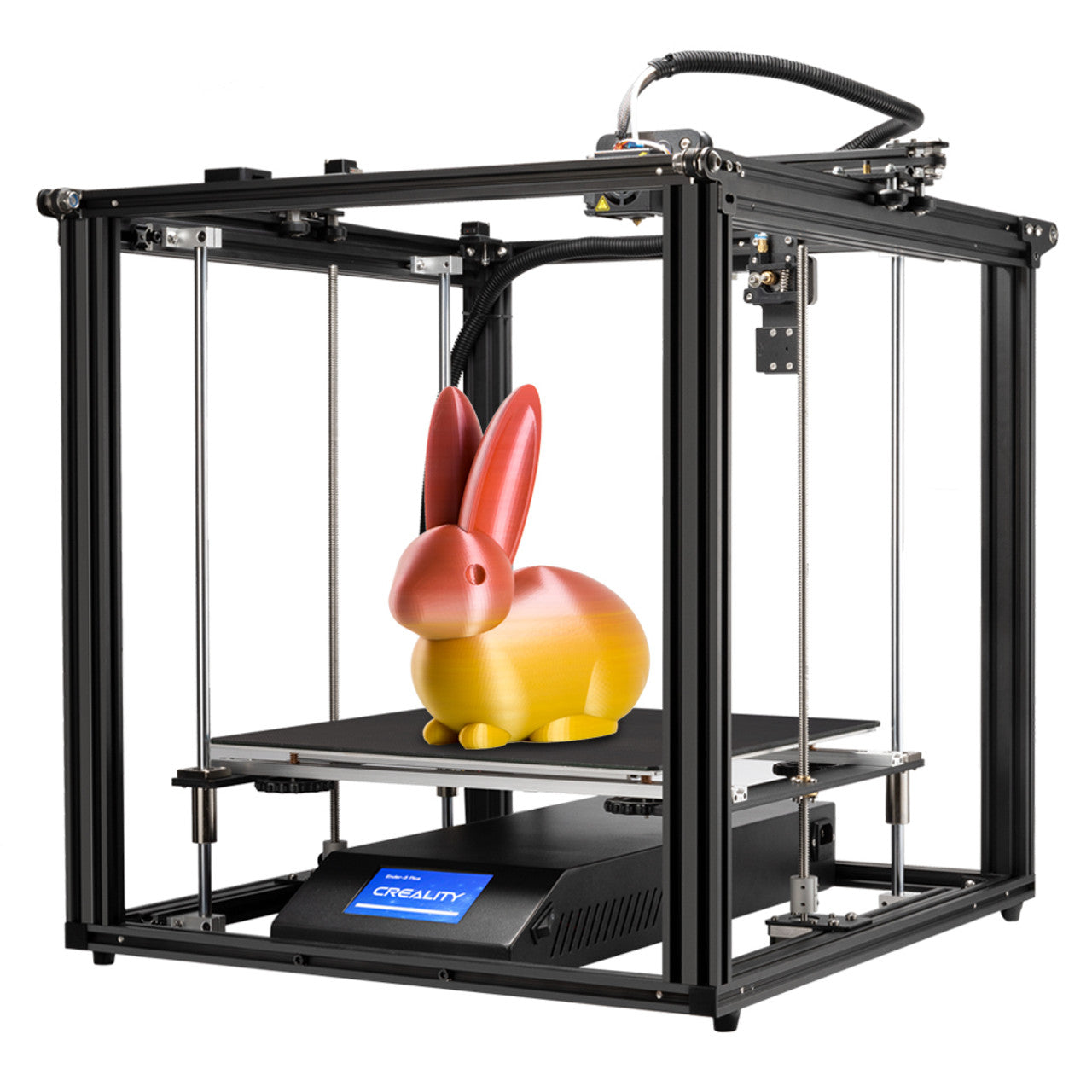

Thinking about purchasing your first 3D printer? It’s exciting times in the 3D printing industry and even better for new enthusiasts. With the technology itself ever improving and the cost to start becoming very affordable, there’s never been a better time to purchase your first 3D printer.

3D printers come in many sizes and capabilities to suit your needs and price points. To assist you in picking which printer is right for you, we've compiled a list of 10 things you should know before buying a 3D printer.

- Types of 3D Printers:

While the meaning of a 3D printer is the creation of a 3D object, the way that object is created can differ depending on the type of printer you purchase.

Fused Deposition Modelling (FDM):

FDM technology works by building up an object, layer by layer, from a solid material (filament) that has been heated to a melting point and extruded through a small nozzle. The majority of 3D printers on the market use this type of technology.

Stereolithography (SLA):

SLA printing uses ultraviolet laser beams to harden a model layer by layer from a pool of photosensitive liquid (resin). Stereolithography printers are commonly used for smaller prints that require fine details. SLA printing also has post-printing requirements, such as cleaning and curing the resin via UV light.

Selective Laser Sintering (SLS):

Comparable to stereolithography, SLS uses lasers and powders rather than UV light beams and liquid to create objects. The powder is melted using a laser to produce a layer of printed material, this method can be used to produce metal models, but machines are much more expensive than other options mentioned.

- Build Your Own 3D Printer or Purchase One:

Given that the 3D printing industry is made up of builders and creators, it seems natural that many individuals would wish to try their hand at building a 3D printer on their own. If you want to go this path, you can get instructions and 3D printer kits online, but this process can be more expensive than current entry-level printers and take days to build. Your ultimate choice will be based on whether you want to experiment with the technology or just want to get printing right now. For beginners for certainly recommend the second option, though, so assembly is still required for most printers.

- Price:

Ultimately price and budget dictate what printers we can choose from, and thankfully there are good quality low-cost options for new users up to commercial machines costing tens of thousands. As the industry continues to grow, this will see prices decline and quality increase,

- The printing materials:

For FDM printing Poly Lactic Acid (PLA) is the most commonly used filament, especially for beginners, followed by polyethylene terephthalate glycol (PETG) and acrylonitrile butadiene styrene (ABS). Other materials include flexible filaments, carbon fiber, silk, glow-in-the-dark, etc. The range of colors and materials available is also growing and improving, which is just as exciting as the improvement in the machines themselves.

For SLA printers, there are different types of resins available. The most common is your standard ridged resin, but water-washable resins are becoming more popular for easier post-printing requirements. SLA resins also have high strength, clear, flexible options available, as well as resins for dental and jewelry making.

- Print Quality:

Print resolution and print speed are two factors that determine both the time your print will take but also the quality. For example, if you want a high-quality print, then you’ll need to lower the print resolution and print speed, the trade-off being this will increase the time it takes to print. Vice versa, by upping the resolution and print speed, you will print the object quicker but at a lower quality and have a higher risk of failure.

- Creating a 3D Model:

A 3D model may be obtained in one of two ways: by creating it yourself or by downloading an existing file from the internet. To create a model yourself, you’ll need to use a CAD program. This can take a while to learn if not experienced. Downloading existing files is a much easier alternative, and many websites offer free and paid files.

Safety: You must always be careful around your 3D printer. It has hot moving parts. PLA, for example, prints at around 200c nozzle temp and generally on a heated print bed at 60c. Most printers now come with thermal runaway sensors to stop the fire risk, but it is worth double check it. Overall 3D printers are safe, but you still need to be mindful.

- STL Files:

When downloading or creating your 3D object, you’ll need to download the STL file. If creating models most CAD programs will allow you to format in this. If downloaded generally, the STL file is the only file available.

- Software for Slicing:

You must run them through a slicing program once you have an STL file for the model you wish to print. Slicing basically "tells" your printer how to print your object. It offers guidance on the required number of layers, the printer's starting location, and the model's solid or hollow portions.

Once you have your STL file, you must run it through a slicing program. Again, there are many free and paid options available. In your slicer is where you can set your print temp, speed, layer height etc. Once you have set all the settings for the print, you hit a slice, and it slices your model into the layers for the 3D printer to print. It also creates the G-code. This code is essentially the instructions for the printer. Telling it where to go, at what speed and temp etc.

- Community:

3D printing is a very hands-on hobby, and from this hobby, a large and supportive community has been created. The community is important, be it for feedback on printers you’re looking at, helping to troubleshoot any issues or helping with printer upgrades. There are so many videos on YouTube, blogs and Facebook groups, all designed to help and guide you on your 3D printing journey.

At 3D META, we also like to provide that sense of community with our customers, focusing on customer service. We like to think we work hard to offer our customers the best product and service at the best price and are always available to help or answer any questions. So feel free to get in touch if you have any questions.